Nowadays, people are more concerned about the environmental impact and are turning to recycled products to reduce their carbon footprint. One product that has been gaining popularity is plastic timber, also known as plastic lumber. Made from 100% recycled plastic, it serves as a synthetic alternative to traditional wood.If you’re considering using recycled plastic lumber for your outdoor projects, you might be researching how different it is from traditional wood. Does it offer the same strength, functionality, appearance, and shelf life?

In this blog, we will take a closer look at the science behind plastic timber, how it’s made, and why it’s proving to be a stronger, more durable alternative to traditional wood.

The Science Behind Plastic Wood: How it is made

Waste plastic is transformed into high-quality, cost-effective plastic lumber for outdoor and construction uses using an innovative recycling process.

- Identifying and Processing Recycled Plastic

The first step in the production process is gathering post-consumer and industrial waste that is 100% plastic. After being cleaned and sorted, this garbage is shredded into tiny plastic particles.

- Forming Timber Shapes by Melting and Moulding

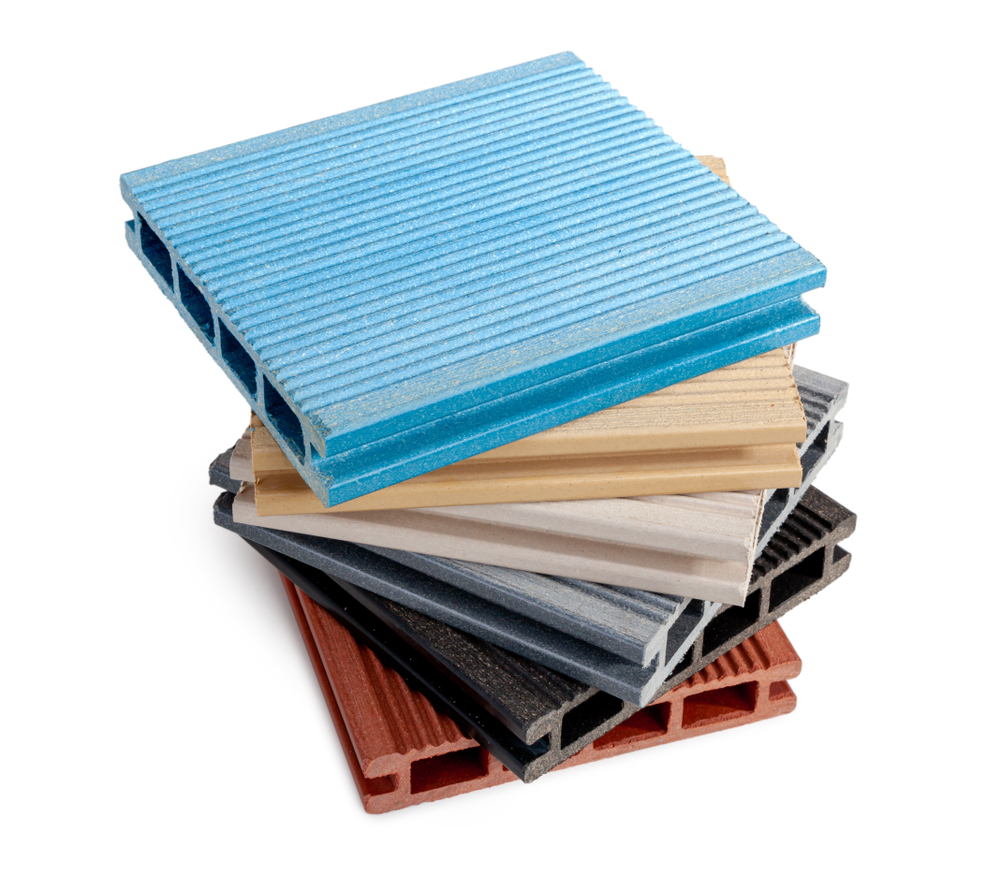

Using moulding procedures, the plastic granules are melted at a regulated temperature and formed into artificial wood structures. Weatherproofing, UV resistance, and durability can all be improved with additives.

- Final Finishing and Cooling

To get a smooth and superior finish, the moulded plastic wood is cooled, sliced, and polished.The end product is a durable, cost-effective substitute for traditional wooden timber.

The long-lasting qualities of plastic lumber continue beyond its production method. It requires less maintenance than traditional wood since it is resistant to dampness, rot, and insect damage. For outdoor and construction jobs, its synthetic nature makes it a more durable and robust option.

Why does plastic timber last longer than wood?

In comparison to traditional wooden timber, plastic wood is designed to be resilient to common problems that affect natural wood. This is why it performs better than conventional materials:

Resistant To Insects and Bugs

When we question the durability of plastic timber we need to consider what it is made from. The vast majority of plastic lumber is created from recycled plastic or waste. With plastic having one of the largest life cycles on the planet you could certainly make the argument that plastic timber is strong and durable. The majority of plastic timber’s strength performance is derived from its resistance to outside elements. Traditional wood timber, after a while, succumbs to damage from termites and other wood-eating insects. This is a process that occurs especially in products that are intended for outside use. But it can occur anywhere. Whilst with wooden lumber, you will experience this natural process of decay, with plastic wood, insects such as termites are unable to cause damage.

Strong Against Rain and Moisture

Not only is wooden timber likely to succumb to damage from insects but it also experiences damage from water and the elements. Over time, without consistent maintenance (painting, staining, sealing) wooden timber will crack, rot and experience discolouration as a result of rain and moisture. Plastic timber, on the other hand, is relatively maintenance-free because it is extremely durable and reliable in wet conditions. If we consider plastic timber’s moisture-resistant qualities you could argue that it outperforms traditional wooden structures in durability and reliability.

Strength in Versatility

One of the strengths of plastic timber is its versatility. You can make use of recycled plastic lumber in a great number of ways. You may wish to use it for decking, cladding, window/ door frames or outdoor furniture. Traditional timber, and its tendency to absorb moisture, makes it ineffective in some construction projects. With plastic timber, you have greater flexibility and all-around performance, which gives traditional timber a run for its money.

Making Your Choice

We hope this article has provided an insight into the key differences between plastic and wood timber. If you are in the midst of, or indeed looking to start, a home restoration project and have the choice of wooden or plastic timber, you may be torn. It is true that both products have characteristics that make them suitable for different projects. If, however, you are hoping to determine whether plastic lumber is as strong as traditional wooden timber, and this would be a deciding factor, we would argue that it is certainly comparable. In some key areas (longevity and general durability) the case could be made that plastic timber is an even stronger performer than traditional wood.

Explore a cost-effective solution for your next project at Eco Plastic Wood today. Contact us now!